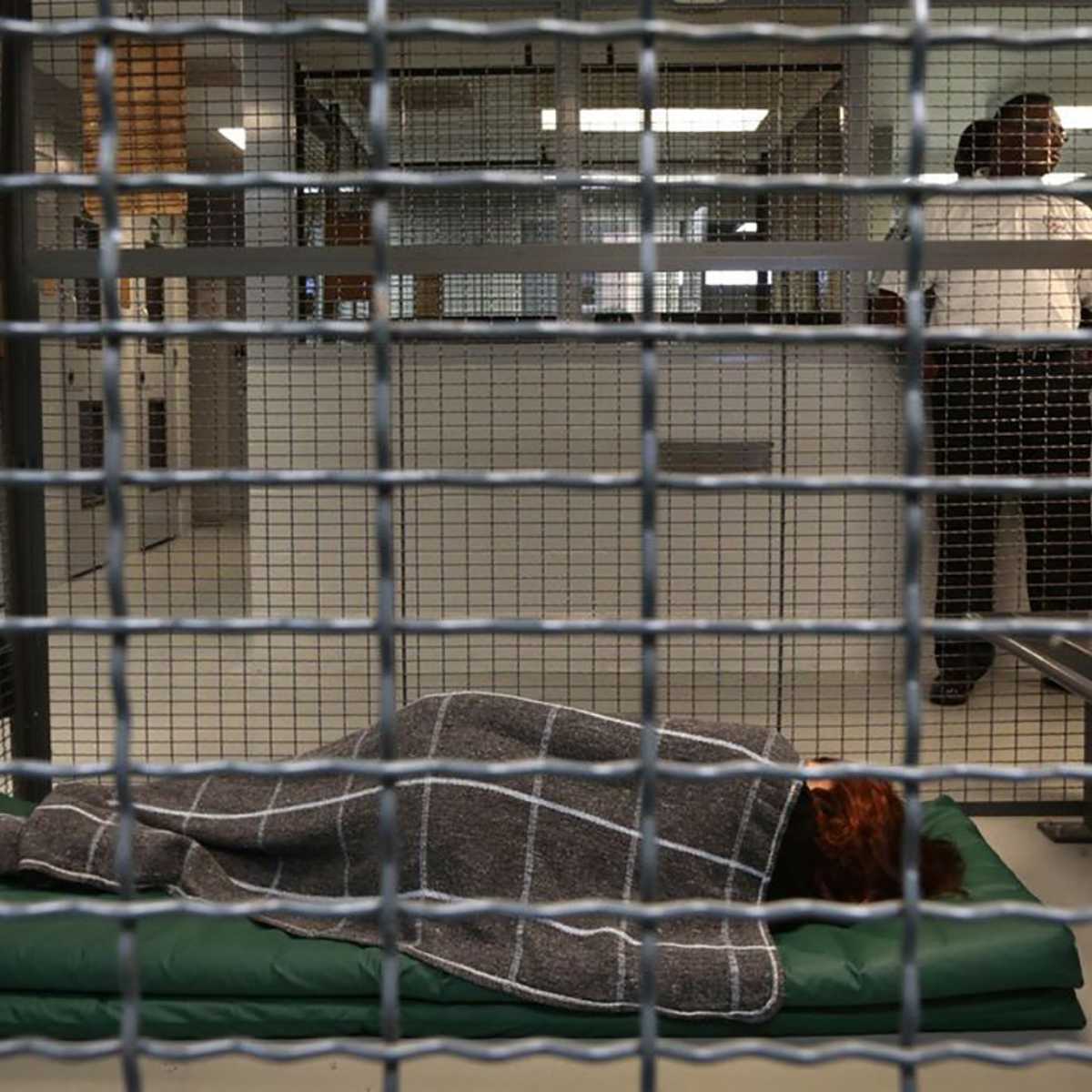

Supervised Temporary Holding Cell

WireCrafters Style 840 partition system is used to build prisoner holding cells in correctional and detention centers across the country. Our Style 840 Holding Cells are designed for supervised temporary confinement while prisoners are being processed or detained for a short period of time. Because of the versatility of our wire partition system, the strong wire partition panels can be configured to meet facility needs utilizing our standard parts.

STOCK PANELS

Panels come in one foot increments from 1′ to 10′ wide, and in heights of 4′ and 5′.

SECURITY TO THE MAX

Our unique wire partition cage design prevents access to all hardware from the secure side of the holding cell enclosure. Heavy duty options are available for facilities requiring enhanced security.

UTILIZE EXISTING SYSTEMS

Our open but secure design allows free circulation of existing lighting, HVAC, and fire suppression systems throughout the holding cell.

Holding Cell Doors & Ceilings

A hinged door with a secure lock device keeps detainees and prisoners in the holding cell. Ceiling panels constructed of the same material completes the holding cell, and our unique design prevents access to all hardware from the secure side of the holding cell enclosure. The wire partition holding cell system installs quickly with standard hand tools using heavy 3/8″ assembly hardware. Our open but secure design allows free circulation of existing lighting, HVAC, and fire suppression systems throughout the holding cell. Heavy duty options are available for facilities requiring enhanced security.

Holding Cell Lock Details

WireCrafters standard mortise cylinder lock, a self-locking device with a spring action tongue, can be used in this application. We also offer an institutional high security dead latch lock. Top and bottom slide bolts may also be added to the door. Customer specified locks may be integrated into the system as well. Review our custom locks section to see some examples of locks we integrated into our system.

Benches & Seating

Anchorable 11-gauge steel benches may be added to the cell or purchased separately.

- Seat: formed 11 gauge sheet metal, 13″ wide.

- (Optional cuff rail adds 4″ to seat width)

- Legs: Pedestal-style, welded 2″ x 2″ x 14 gauge steel.

- Mounting plates: 4″ x 9″ base plates with four 3/8″ anchors.

- Lengths: 4′-0″, 6′-0″ and 8′-0″. Corner units available.

- Options: Seat width, bench length, mounting brackets, cuff rail.

Key Holding Cell Features

- Twenty standard sized panels 4’0″ or 5′-0″ high, by 1′-0″ to 10′-0″ wide.

- Stack two or more panels between posts to reach wall height.

- Standard size panels work in ceilings and walls.

- Custom size panels and special heights available.

- Hinged, double hinged, sliding and vertical rise doors available.

- Sliding doors have patented tamper resistant latch mechanism.

- Angle frame design gives installer clear access to hardware, speeding installation.

- Assembly hardware is inaccessible from the secured side of the partition.

- Standard 3/8″ mounting hardware is the heaviest in the industry.

- Heavy duty options available.

- Panels may be ordered with any mesh, expanded metal, sheet metal or clear polycarbonate.

Related Posts

High Clearance Wire Cage Supports Specialized Equipment Needs

Business, Case Studies, Product, Safety, Secure Storage Cages, Security, Separation, Tenant Storage Lockers, Wire Partitions

WireCrafters collaborated with McCormick Equipment Company to deliver a secure and efficient wire partition solution for an undisclosed customer. The project required a customized approach to meet specific facility needs, including controlled access, enhanced safety, and optimal space utilization. By combining WireCrafters’ durable wire partition systems with McCormick’s application expertise, the team was able to provide a solution that aligned with the customer’s operational goals.

Read More

Custom Stairwell Safety Solution for Downtown High-Rise

Business, Case Studies, Product, Safety, Secure Storage Cages, Security, Separation, Tenant Storage Lockers, Wire Partitions

In a high-rise, multi-use building project in downtown Austin, Texas, Swinerton GC required a safety solution to prevent individuals from jumping over stairwell openings to access restricted floors below. The unique challenge called for a system that could be securely installed within an active construction environment without compromising site efficiency or safety standards. Cisco-Eagle brought in WireCrafters to deliver a custom-designed wire partition system to enhance stairwell safety while aligning with the space's architectural and operational demands.

Read More