Technician Locker Systems

The Solution for Distribution Centers

WireCrafters® manufactures Technician Lockers, often referred to as Mechanic or Distribution Lockers.

This unique system allows for drivers/technicians to enter the facility in a controlled environment and have all of their parts sorted and waiting in their designated lockers. A simple pad lock can be utilized, however WireCrafters also offers a variety of locking systems in biometrics, key card readers, key pads, etc.

On the reverse side the parts manager can load all lockers from the inside of the WireCrafters cage system. All items stay separated and inaccessible from the technician side of the locker bay, allowing the driver/technician to only access their designated cell.

WireCrafters Technician Locker Systems are ideal for Distribution Centers, Lift Truck Companies, Cable Companies, Plumbing Companies, Electrical Companies, HVAC Companies, Auto Tech Centers & More.

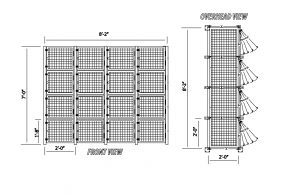

Common Configuration

- 4 Compartments High (ea. 1′-8″H)

- 4 Compartments Wide (ea. 2’W)

- 16GA Galvanized Shelves

- Ceiling Panels

- 2’W x 1′-8″H Door Size

- 2′ x 2′ 10 GA Welded Wire Mesh

- Mesh Welded to Angle Frame

- 2′ x 2″ 14GA Sq. Tube Posts

- Hinged Doors

- Padlock Hasps

Related Posts

Custom Wire Partition System for Medical Equipment Storage

Business, Case Studies, Pallet Rack Backing & Enclosures, Product, Safety, Secure Storage Cages, Security, Separation, Storage Lockers, Tool Cribs, Wire Partitions

WireCrafters partnered with Lynch Material Handling to deliver a wire partition solution for a medical equipment manufacturer seeking to organize better and secure its facility. The application required a durable, flexible system that could adapt to the operational needs of a highly regulated environment while maintaining clear visibility and access control. By leveraging WireCrafters’ wire partition systems, the project provided a practical balance of security, organization, and long-term performance to support the manufacturer’s day-to-day operations.

Read More

Securing High-Value Inventory Across Multiple Retail Locations

Business, Case Studies, Pallet Rack Backing & Enclosures, Product, Safety, Secure Storage Cages, Security, Separation, Storage Lockers, Wine Storage Lockers, Wire Partitions

WireCrafters partnered with Northwest Handling Systems to deliver a reliable physical barrier solution for Total Wine, supporting loss prevention efforts across more than 20 store locations nationwide. The project focused on installing rack enclosures within storage rooms to help secure high-dollar inventory from theft while maintaining visibility and accessibility for authorized staff. With consistency, durability, and scalability as key requirements, this solution enabled Total Wine to standardize protection for valuable products across multiple facilities.

Read More