Safety, a word you hear on a daily basis. You have countless meetings on profitability, streamlining, and safety. All of these affect your company - from OSHA fines and liability claims to just making sure that your employees are content and safe. There is always room for safety improvement. We want to share with you another way to ensure a safe work environment for your employees while keeping the all-powerful OSHA happy.

Woven and Welded Partition Machine Guarding

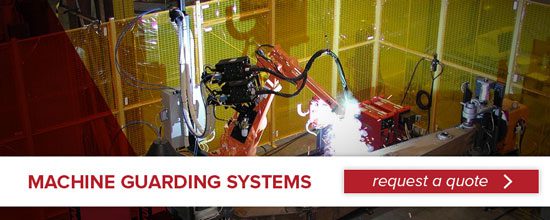

Commonly found in weld cells, robotic cells, press brake equipment stations, laser cutting operation areas, metal stamping and folding areas, and punching stations - machine guarding is an industry standard thanks to OSHA. Keep your machines behind a barrier to keep personnel and other equipment out of harm's way.

WireCrafters offers both woven and welded wire mesh panel systems to separate and protect equipment and personnel. These fully-framed woven wire or welded wire mesh panels bolt to posts forming a strong, secure barrier around automated equipment. Unlike light curtains and switch mats that are subject to electrical malfunctions, these safety systems are always on guard. Wire partitions are virtually maintenance free, which is essential in an industrial environment.

Utilizing machine guards is a strong and economical solution to a plant's safety needs. WireCrafters' Machine Guarding System delivers versatility because it allows easy integration of access doors with system controls, among other customizable traits.

How's It Work

The WireCrafters standard physical barrier system combines a 5' high panel and 5’-3 1/4” high post. Panels come in 1’-0” wide increments up to 10’-0” wide. These panels bolt to a 2” square post. Hinge doors 3’-0” and 4’-0” wide with latches and interlocks are available in stock also. This design complies with safety standards for machine parameter guarding.

Customization

WireCrafters machine guarding systems utilize a modular wire mesh panel design which allows for multiple combinations of standard parts to meet your specific space and guarding requirements. We offer a full line of special colors and accessories such as hinged doors, sliding doors, lift out panels, and locking latches to integrate with your machine guarding system. We can also work with you to get the right dimensions and height required for your necessary space.

We have a variety of meshes to meet requirements for heavy, medium, or light duty jobs. Also, we can provide polycarbonate and sheet metal partition panels to ensure the proper safety for your machine guarding needs.

OSHA

Not only are we OSHA compliant but we are also ANSI/RIA R15.06-2012 compliant with all of our products. This means that not only do we have the approved partitions by OSHA but we also create barriers that safely collaborate with the machines, as according to the ANSI/RIA R15.06-2012 change. If you would like more information about the OSHA inspections, click here.

OSHA comes to inspect your facility looking for hazards and any other issues. Keep machines guarded and secure to ensure a safe working environment for everyone. Machine Guarding has many possible applications. Check out our website for more information or contact us and we can have a local dealer in your area to help define your machine guarding needs.

To learn more about our Machine Guarding Systems or get a quote, please click the image below.

1 thought on “How To Ensure A Safe Industrial Working Environment With Machine Guards”

Comments are closed.